Compressor Station Safety Fundamentals

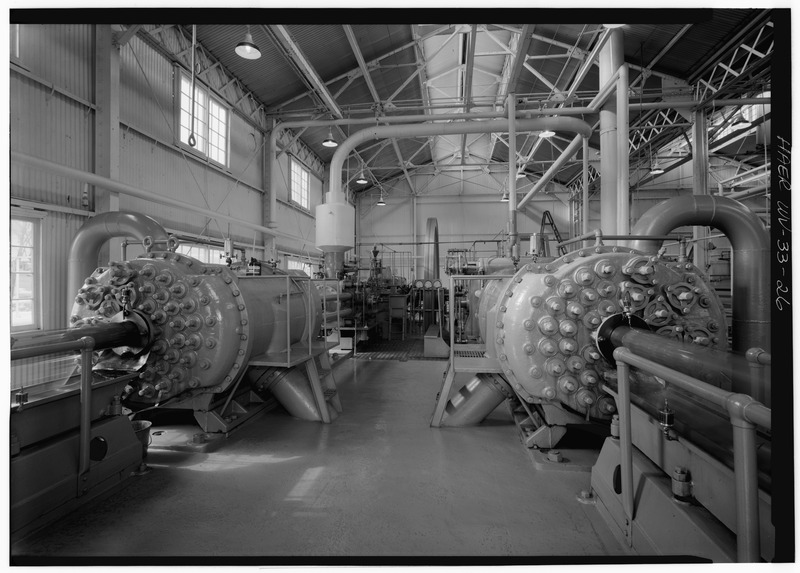

As energy production continues to increase as the result of natural gas development through fracking in areas like the Marcellus and Utica shales, more infrastructure must be developed in order to get materials from producers to consumers. For natural gas, this means using compressor stations to relay gas through a pipeline system. As gas travels through a pipeline it loses pressure through frictional losses with the pipe wall. In order to efficiently flow gas it is necessary to boost the pressure every 40-100 miles. This task is performed using a compressor station, which is a facility that includes one or more compressors, usually housed inside a compressor building, with a few other attendent pieces of equipment like liquid knockout drums and associated control systems.

While these pieces of equipment are very standard and critical to supplying the energy infrastructure that our modern way of life depends on, recently there has been a significant amount of pushback from local communities in placing this type of equipment “in their backyard”. To some degree, this is understandable, as those who watch the news know that there have been a signigicant amount of events related to compressor stations that have garnered unflattering attention to the industry. This is compounded by the fact that some organizations that operate compressor stations are newer to the process industries and a not as familiar with the full set of tools required to properly implement process safety as some of the more established oil and gas companies that have been doing this for over a hundred years.

The primary set of requirements for safety related to a compressor station comes from the Department of Transportation (DOT) in the Code of Federal Regulations as 49 CFR 192.163 through 49 CFR 192.173. The text of these regulations is contained in the word document found at the link shown below.

You can see that the document is very short, and while it provides the key requirements that need to be achieved, it does not go into a lot of detail on exactly how the requirements can be achieved. For instance, 49 CFR 192.173 simply states: “Each compressor station building must be ventilated to ensure that employees are not endangered by the accumulation of gas in rooms, sumps, attics, pits, or other enclosed spaces.” An unsophisticated reading of this simply clause might lead one to believe that the requirement could be met by simply leaving a door open to allow the station to “air out” as required. A more sophisticated reader might have a different interpretation. That reader might understand that there are a large number of potential leak locations and leak sizes that are possible, and that those leaks need to be mathematically modelled to determine the leak rates, which are a function of pressure, temperature, and composition of the gas. After determining the leak rate, one would also need to consider where the released material will go considering the size of the room, the osbtructions (objects) that are in the room, and the affect of the HVAC system in moving the released gases around and out. If this type of analysis determines that pockets of gases could reach flammable concentrations, then detection and alarming of the leak along with potential automatic actions to “shut in” the compressor might also be required. That single sentence of regulation might easily be interpreted to require a very sophsiticated mathematical engineering study of potential leaks in the system along with the potential specification of engineering safeguard equipment like gas detectors.

The four pages of regulations provide high level requirements, but the amount of engineering detail required to meet those requirements is not insignificant. The best practice for the design of compressor stations with respect to technical safety should include, or at least formally consider, the following technical safety studies.

- Hazards and Operability Study (HAZOP) – to understand and identify hazard scenarios that are possible and ensure an appropriate amount of safeguards for those scenarios

- Layer of Protection Analysis (LOPA) – to obtain a deeper understanding of higher risk scenarios and establish performance targets for safety instrumeneted systems for emergency shutdown

- Facility Siting Analysis – Using quantitative dispersion modeling of releases (including emergency blowdown) and explosion modeling to ensure that the distance between the facility and neighobors is sufficient to prevent the dangerous affects of these events from harming people off the compressor station site

- Safety Instrumented System Design Basis – to develop a design and maintenance program that will achieve quantitative reliability targets for specified emergency shutdown systems, and also provide the appropriate documentation for design and ongoing maintenance and testing – the subsequent testing program will also be applied to other safety instrumentation including relief equipment and fire and gas detection equipment

- Fire Detector Mapping – Determining the optimal number of placement of fire detectors to detect a compressor fire and cause an appropriate response action

- Gas Detector Mapping – Model gas releases to determine if gas detection, potentially with automatic shutdown, is required, and if so, determine the appropriate number and placement of gas detectors

- Pressure Relief Design Basis – Determine the number, location, and size of required relief devices as a function of the process conditions, and equipment items utilized at the compressor station

- Cybersecurity Assessment – Design and/or audit the design of control systems (often remote supervisory control and data acquisition

[SCADA]) using standards like API 1164 and other technical assessments

While this may seem like a lot of work, it is actually not, especially if you partner with an organization for which these activities are a core compentency. Each of the above activities should not require more than a couple of days of effort due to the manageable size of a compressor station. Kenexis is not only experienced with all of these activities, we have developed best in class software to not only perform the activities, but also to allow ongoing management of the resulting safety equipment and studies. This software is cloud-based, allowing a central engineering staff to seamlessly manage dozens or even hundreds of facilities. Please feel free to contact us for more information.

Coming soon, we expect to provide you with a discussion of using a protocol template inside the Kenexis OpenAudit software to perform a basic safety audit of a compressor station…