Where it Leaks, Accumulates, and Migrates

The process industries are starting to adopt performance-based design techniques for fire & gas detection systems versus prescriptive models. This is increasingly important after recent fire & explosion events have caused major loss of life and asset damage. Meanwhile, some continue to use methods for layout of gas detection based on uniform spacing (prescriptive models) that date back more than 25 years. Even when applying performance-based design techniques, the ‘gas volume detection’ principal is valid in terms of detecting and mitigating a large explosion event; however, this same method of designing and assessing detector coverage can result in large number of detectors and a costly design.

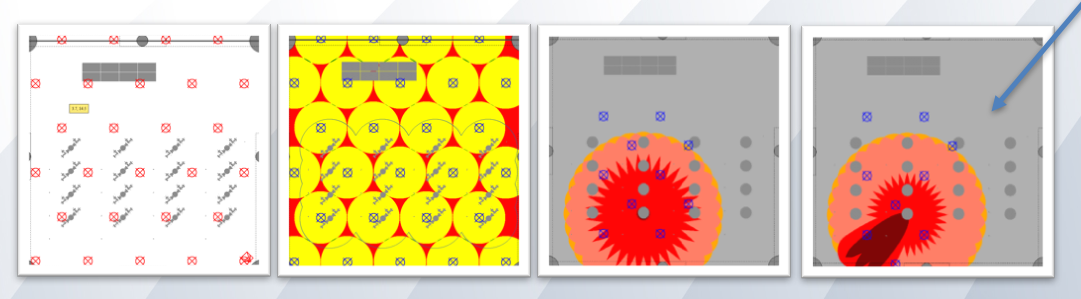

Kenexis challenges the need for volume detection by using sophisticated modeling of gas release scenarios using several methods (subsonic and supersonic) of computational fluid dynamics (CFD) for hazard modeling and risk analysis techniques. These techniques align with the ISA TR 84.00.07 guidelines for combustible gas detection on a scenario-by-scenario basis, and this breaks the paradigm that CFD can only be used sparingly on complicated gas dispersion problems.

Kenexis demonstrates for its clients that the practical application of CFD modeling and probabilistic risk analysis to improve on the performance of gas detection systems while at the same time, reducing unnecessary conservatism in the number of detectors.

Using Kenexis work practices, we are able to mathematically validate the proper detector mapping based on the above criteria and at the same time usually reduce the number of detectors while providing acceptable coverage models. In a recent study presented at the ISA UAE Conference in May 20016, we demonstrated a reduction in the prescriptive model from 27 detectors to 14 detectors in a performance based model while only reducing the coverage from 91% to 86%. Thereby eliminating 13 detectors, that in essence were only providing 5% of the total converge.

This results in a substantial reduction in capital expense and installation cost, reduced conduit burden and the reduction of the maintenance cost of the life of the platform.