Dangerous Myths about Gas Detector Placement

Recently I have been involved in reviewing existing gas detector designs where significant leak incidents have occurred, but the gas leak was not detected by the existing gas detection array. In several of these cases, I have seen detector placement performed using common heuristics (rules-of-thumb) that resulted in very poor design choices. Unfortunately, these rules-of-thumb are extremely common and well known even though they are dangerously bad practices. In some cases, I even found written design guidance requiring that some of these techniques be used.

While there are many bad rules-of-thumb in gas detector design, the two common ones that I have run into recently are as follows:

- Place gas detectors as close to the leak source as possible.

- Gas detectors have a range that allows them to detect leaks that are within ## feet of the detector

Either one of these myths is a bad design practice on its own, but when combined together their danger multiplies.

Let’s start with rule #1. It would seem the placing a gas detector as near as possible to the leak source is a reasonable practice, but in fact, it is not. In order to understand why one needs to consider the dynamics of a release of gas from a pressurized piece of equipment. When a gas is released from a hole in a piece of equipment, the material escapes at a rate that is usually calculated using equations that result from the work of Bernoulli and Torricelli for sharp edged orifices. Equations are available in Guidelines for Chemical Process Quantitative Risk analysis from the AIChE CCPS. The released material forms a jet which is often high velocity. This narrow jet subsequently expands in width as the momentum of the released material decreases. The width of the cloud increases as the distance from the release point increases, and the concentration of in the cloud is generally normally distributed from the centerline of the release out to the edge. As the distance away from the release point increases, the overall concentration begins to decrease as air from the surroundings is pulled into the gas cloud, diluting the released material. At some point away from the release point the cloud will reach a maximum width where the effect of cloud dilution begins to overcome the widening of the cloud from momentum decay effects. It is here where the released gas cloud is at its maximum width that gas detectors are best placed, not near the origin of the release.

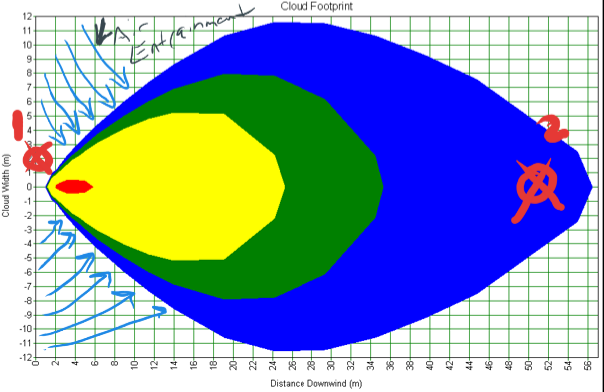

If a detector is placed very near the release point the width of the gas cloud is at its narrowest and the release velocity is highest. This high velocity of release has a second negative impact to consider. If the detector is near a gas release point, but not directly in its path, the concentration of gas will actually be lower than normal, because a high velocity release will pull air from the surroundings in to the jet via the venturi effect. So not only is the jet not working its way into the detector, the jet’s venturi is actually pulling air across the detector. All of these concepts are shown in the figure below where a dispersion model (gaussian) is estimated for a typical gas released. This figure clearly shows how the cloud width increases with distance, and then decreases again when dilution overcomes momentum effects. The effect of fresh air dilution via venturi effects is also superimposed on the figure.

In the figure above, the blue represents a detectable gas cloud, let’s say 20% of LFL It is clear that if the detector is placed about 26 meters from the leak source, the gas cloud is at its widest and the probability of detection is highest because the detector can be more than 10 meters away from the centerline of the release, but still be inside the detection limits (at 2 meters away from the leak point the detector would have to be less than 1 meter off centerline to go into alarm). Two detectors have been placed in this figure. The first detector, which is very close to the detector would not go into alarm because it is not in the path of the release, and is in the path of the venturi action that is pulling fresh air into the release jet. The second detector, while more than 50 meters away, is solidly in the gas cloud and will go into alarm in the event of the release.

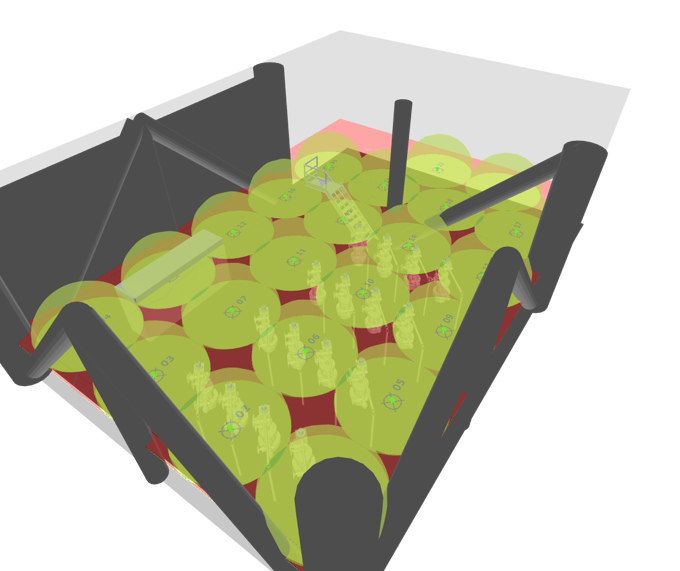

The other myth purports that when a detector is placed in a given location, any gas release within a given radius away from that detector will cause it to go into alarm. I’ve seen numbers like 100 feet bandied about for this rule of thumb. This “rule” is patently false, and you need no more evidence than the figure above where a detector that is 1 m away does not detect the release but one that is more than 50 m away does. The ultimate truth of gas detection is that unless the gas cloud intersects with the gas cloud where the gas cloud concentration is above the set point of the detector, the detector will not go into alarm. The release point and size of the gas cloud are of utmost important here, not any attributes of the detector itself. This fiction is reinforced by the inferior geographic coverage method of gas detection coverage modeling, that is quickly becoming considered obsolete by virtually all of industry. Geographic coverage makes the assumption that if a gas detector is placed in a given location, then any gas release that occurs within its “sphere of coverage”, as shown in the figure below, will be detected by the gas detector.

While this approach is better than nothing, it is only slightly so… The fallacy in this approach is that it assumes that all gas releases are spherical from the release point, which a quick look at the prior figure shows is completly untrue. Unobstructed gas clouds (gaussian model) form a elliptical shape with the release point at one edge.

Ultimately, good gas detector placement REQUIRES a knowledge of the gas release. Releases must be modeled to understand the expected dimensions of the gas clouds, their frequences, and the locations from which they originate. Using easy rules-of-thumb, and even slightly more sophisticated geometry only approaches can result in dangerously bad designs.