Determining and Documenting Leak Tightness Requirements

Have you ever had an audit reveal that your safety requirements specification documentation was inadequate for valve leakage requirements?

The ISA/IEC 61511 standard is clear that the successful criteria for operation including leakage rates for valves used as a final element in a SIF are described in the Safety Requirements Specification for the SIF.

ISA/IEC 61511 Functional Safety – Safety Instrumented Systems for the Process Industry Sector Standard, Section 10.3.2 SIS safety requirements states,

These requirements shall be sufficient to design the SIS and shall include a

description of the intent and approach applied during the development of the SIS safety

requirements as applicable:

-

- a description of SIF process output actions and the criteria for successful operation, e.g., leakage rate for valves;

Even if you specify tight shutoff (TSO) you need to document the acceptable leakage rate requirements to meet a successful operation of the SIF to meet the ISA/IEC 61511 standard.

Before recommending tight shutoff valves, it is important to recognize that minor leakage through a valve is a significant problem in some cases and is acceptable in other situations. Engineers tend to error in the safe direction and recommend tight shutoff valves. This tendency results in a very expensive capital expense and requires additional testing and potential removal and refurbishment cost than may be required for the SIF.

Standards do not standalone, they work with each other and are applied in different situations. Some of the standards that define valve leakage requirements include:

ANSI/FCI 70-2 Control Valve Seat Leakage

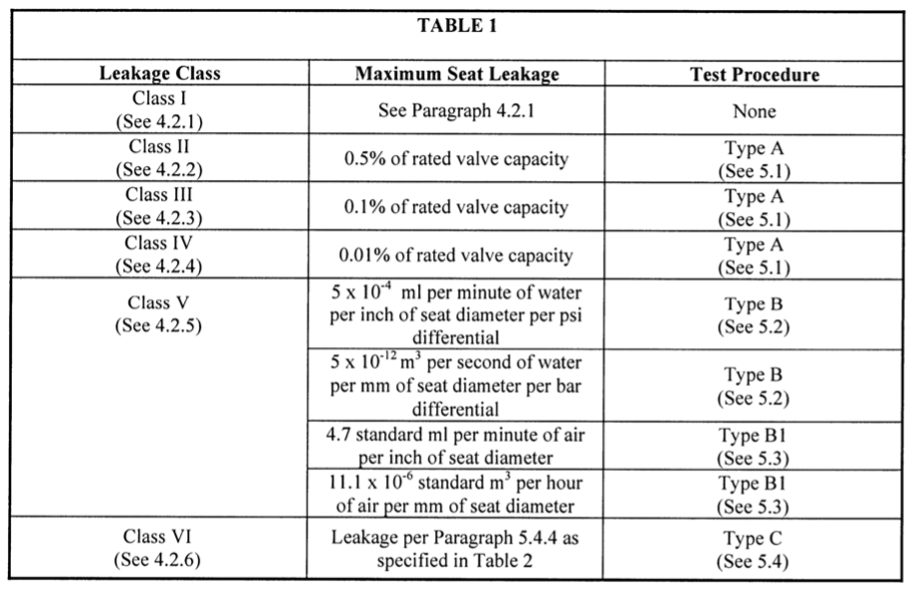

Describes the classes of valves based on leakage requirements. This standard establishes six classes of seat leakage for control valves and defines the specific test procedures to determine the appropriate class.

Table 1 below from the standard, defines the six leakage classes.

IEC 60534-4 Industrial-Process Control Valves – Part 4: Inspection And Routine Testing

Specifies the requirements for inspection and testing of control valves manufactured in conformity with the other parts of IEC 60534.

API 598 – Valve Inspection and Testing

Covers inspection, examination, supplementary examinations, and pressure test requirements for resilient-seated, nonmetallic-seated (e.g. ceramic), and metal-to-metal-seated valves of the gate, globe, plug, ball, check, and butterfly types.

ISO 5208 Industrial Valves – Pressure Testing Of Metallic Valves

Specifies examinations and tests that a valve manufacturer needs to act upon in order to establish the integrity of the pressure boundary of an industrial metallic valve and to verify the degree of valve closure tightness and the structural adequacy of its closure mechanism.

API 6D Specification for Pipeline and Piping Valves

Defines the requirements for the design, manufacturing, assembly, testing, and documentation of ball, check, gate, and plug valves for application in pipeline and piping systems for the petroleum and natural gas industries.

API RP 553 Refinery Valves and Accessories for Control and Safety Instrumented Systems

Addresses the special needs of automated valves in refinery services including emergency block and vent valves, on/off valves intended for safety instrumented systems, and special design valves for refinery services.

The recommended practice states that tight shutoff should be Class V or Class VI.

Tight shutoff is a term that gets used ambiguously in industry. If you specify tight shutoff or bubble tight, then you need to specify how much leakage is tolerable and your validation and periodic function test must determine how much leakage is present.

Additionally, if a tight shutoff valve was specified, which class valve was specified? Note that if you are following API RP 553 for tight shutoff, are you specifying Class V or Class VI? Since Class V and Class VI are soft seat valves, are they going to work in your process?

Since the term tight shut off creates confusion, maybe we should just recommend leakage criteria and not risk using the ambiguous term tight shutoff. However, if another standard states that you need tight shutoff for the specific situation, then that is what you are going to use and document what leakage class valve and the acceptable leakage rate.

For additional information, consider the following previous post on this subject:

https://www.kenexis.com/tight-shutoff-requirements-in-srs/

https://www.kenexis.com/determining-shutoff-valve-leak-tightness-requirements/

WEBINAR

Consider joining us for the recorded webinar on Determining and Documenting Appropriate Leak Tightness Requirements. The webinar will go into detail about the differences between tight shut off and leakage rate methods, the standards, and how to determine the correct leak requirements for your situation.