Reducing Turnaround Time & Costs

In today’s challenging oil and chemicals market, businesses are under immense pressure to maintain operations within tight timeframes and budgets, often yielding only minimal profits. Many facilities are grappling with tough decisions regarding their operations and turnarounds to stay afloat, potentially risking operational integrity in the process. However, there exists a significant opportunity in reducing turnaround time & costs by reevaluating safety system designs.

Traditionally, safety instrumented systems (SIS) were designed primarily to meet compliance standards, dating back as far as twenty years. These designs were typically outsourced to third-party consultants who excelled in reliability calculations but lacked deep insights into the intricacies of refinery and petrochemical plant operations and maintenance. Consequently, these early compliance-driven efforts resulted in extensive documentation stored away in forgotten 3-ring binders, gathering dust over the years.

Over the years, as operations evolve, safety requirement specifications (SRS) in many facilities have drifted from alignment with the actual plant conditions. In certain instances, suggested alterations to SIS design or maintenance and testing protocols were never executed. Consequently, there’s a substantial likelihood that your SIS may no longer adhere to standards due to outdated documentation. Even if the documentation remains accurate, testing protocols are often overly burdensome and fail to optimize downtime and expenses.

Finding Opportunities

Conducting a swift assessment of the SRS—those archived in 3-ring binders—against current operational equipment, evaluating associated risks, and crafting updated SRS and testing procedures can yield significant savings in labor and maintenance costs during regular operations and particularly during upcoming plant or refinery turnarounds. Beyond cost reductions in operational and capital expenditures, the time saved during turnarounds can mitigate lost opportunity costs (production).

We’ve identified several areas where issues persist, leading to inflated maintenance and testing expenses:

Additional Improvements

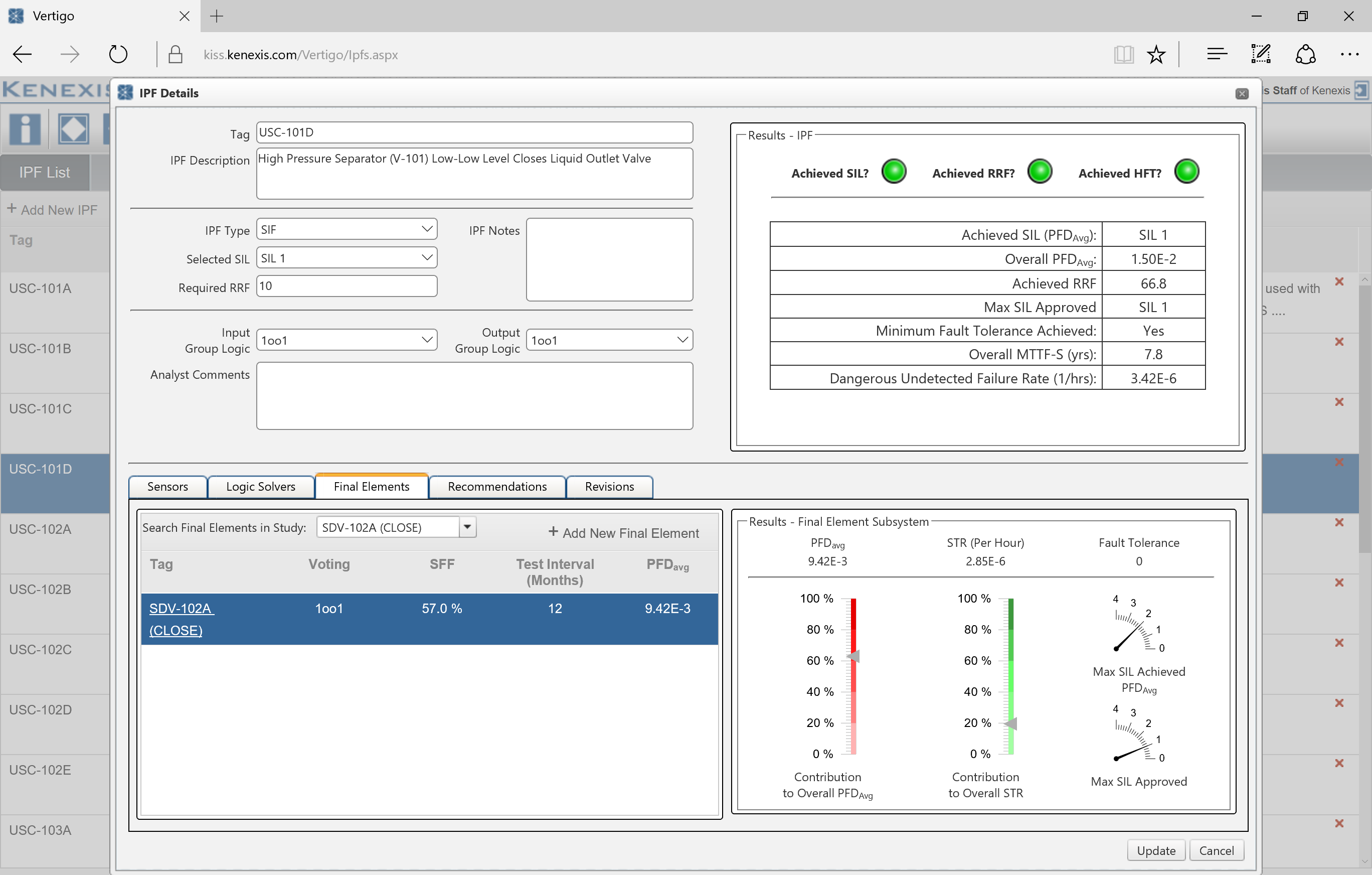

Furthermore, transitioning your Safety Instrumented System (SIS) lifecycle management to digital records streamlines management and compliance efforts, enhancing transparency. Instead of relying on outdated 3-ring binders that fail to reflect the current plant status, data can be securely stored in cloud-based relational database systems. These systems enable tracking of SIS design alongside testing and activation statuses, facilitating automated compliance with API 754 reporting.

A dashboard provides quick access to the status of any plant within the organization or across all plants, enabling identification of problem areas. Users can delve into details to determine the most efficient path back to compliance. Accessible via any internet-connected device and compatible with various browsers, this capability extends from field operators to the CEO, ensuring universal accessibility within the organization.

For more information about reducing turnaround time & costs, contact our team at [email protected]