Recorded Webinars

If you missed any of our live webinars, click the links below to access the recordings.

For the latest updates on our webinars, we invite you to subscribe to our newsletter. Each month, we release a newsletter centered around process safety, along with an announcement for our upcoming live webinar. Rest assured, we prioritize your privacy and will neither sell nor distribute your registration details, and you can opt out at any time.

Register for our newsletter at https://www.kenexis.com/newsletter/

If you like our recorded sessions, you will likely get a great deal from our Process Safety Training Center. All our classes our online and on-demand in our annual subscription service. You can learn more at https://www.kenexis.com/technical-safety-training/

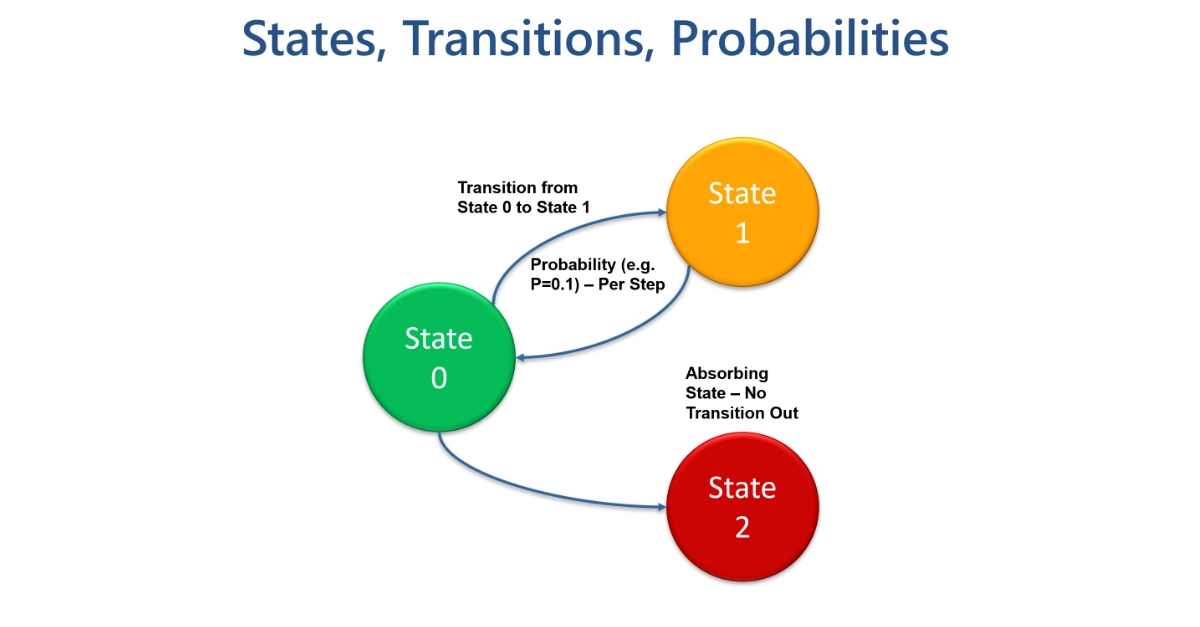

Markov Modeling Overview

Markov modeling is a powerful tool in reliability engineering, known for its ability to model complex systems with unconventional repair schemes and multiple stages of degradation. Although Markov models may appear complex and intimidating, they are ultimately systematic and straightforward. While they are invaluable in certain specialized situations, they often unnecessarily complicate the analysis process and only approximate the accuracy of standard equations. For example, in a simple one-out-of-two voting arrangement, a Markov model merely approaches the accuracy of analytical solution equations but demands significantly more computational effort.

In this webinar, Kenexis President Ed Marszal presents a comprehensive tutorial on Markov models. The webinar aims to demystify Markov models, highlight the scenarios where they are most useful and effective, discuss their limitations and potential inaccuracies, and introduces the methods for their construction and solution.

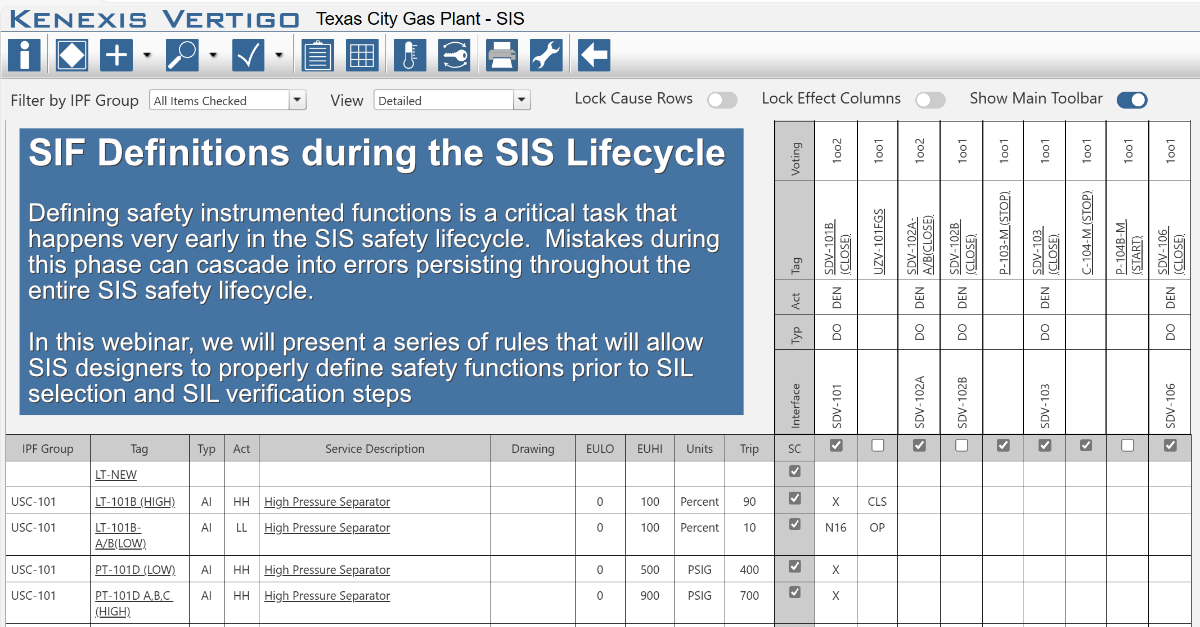

SIF Definitions during the SIS Safety Lifecycle

Defining safety instrumented functions is a critical task that happens very early in the SIS safety lifecycle. Mistakes during this phase can cascade into errors persisting throughout the entire SIS safety lifecycle. Some common errors include associating every action for a sensor in a cause-and-effect diagram, ignoring multiple sensors that can detect a hazardous condition, and improperly voting a large number of sensors – many of which cannot detect a hazard simultaneously.

This webinar presents a series of rules that will allow SIS designers to properly define safety functions prior to SIL selection and SIL verification steps.

SIF Definitions during the SIS Safety Lifecycle

Defining safety instrumented functions is a critical task that happens very early in the SIS safety lifecycle. Mistakes during this phase can cascade into errors persisting throughout the entire SIS safety lifecycle. Some common errors include associating every action for a sensor in a cause-and-effect diagram, ignoring multiple sensors that can detect a hazardous condition, and improperly voting a large number of sensors – many of which cannot detect a hazard simultaneously.

This webinar presents a series of rules that will allow SIS designers to properly define safety functions prior to SIL selection and SIL verification steps.

Failure Rate Units, Format and Conversion

Failure data appears in various shapes, forms, and formats. Different units are often utilized, such as failures per hour, failures per million hours, and FITS. Further, data may be expressed as an overall failure rate, safe failure percentage fractions, and coverage factors. At times, it is separated into categories like dangerous detected, dangerous undetected, and dangerous never detected. Proficiency in comprehending and converting between these presentation types and units is a critical SIS engineering skill.

In this webinar, we cover all commonly used representations of failure rates, explore the various units in which these rates can be expressed, and provide guidance on converting between different formats.

Using Large Language Models AI for HAZOP Automation and Augmentation Tool

Hazards and operability studies (HAZOP) are a critical first step in ensuring safe chemical process facilities. Unfortunately, they are time and resource intensive. Even good HAZOP studies can miss many very significant scenarios or come to insufficient conclusions.

This problem is being exacerbated by the loss of corporate memory that results from experienced personnel leaving the workforce. Research is currently being performed to employ artificial intelligence tools like Generative Pretrained Transformers (e.g., Chat GPT) to assist, or potentially complete automate the HAZOP process. To be effective, the GPT will have to be applied to curated datasets that only contain trusted engineering knowledge that is strictly proprietary – removing the “junk” general knowledge that hampers their performance.

Join President of Kenexis, Edward Marszal, who elaborates on this subject during this webinar. The webinar begins with a discussion of the fundamentals of AI from its inception, starting with expert systems that were abandoned for fuzzy logic and neural networks that underpin modern large language models such as GPT. We then discusses how HAZOP data such as HAZOP and LOPA worksheets can be fed into a large language model and how a GPT will create a model for predicting information in a HAZOP based on training data.

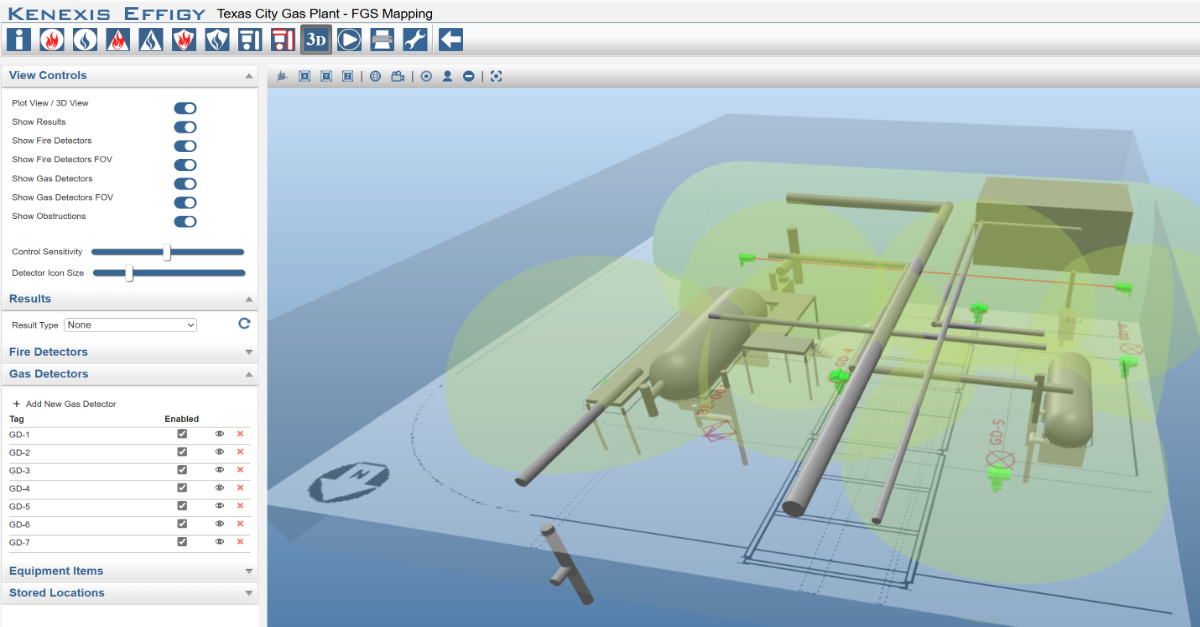

Calibration and Analysis of Gas Detection of Multi-Component Releases

Detecting gases released from chemical processes poses an intricate engineering challenge. Determining the optimal number and placement of detectors is daunting even in ideal conditions. However, the complexity intensifies when a single detector must identify various chemicals or chemical mixtures. Gas detectors are typically calibrated to recognize specific chemicals, meaning exposure to different substances yields disparate measurements.

In this webinar, we delve into the intricacies of detecting multicomponent gas systems versus single-species detection. We’ll explore crucial factors in designing gas detection systems for scenarios involving multicomponent releases.

SIS Commissioning – Open-PHA™ Checklist

Join Kenexis President Ed Marszal in this webinar where he discusses IEC 61511 commissioning requirements, offering insights, examples, and showcasing the use of Open-PHA™ checklists and associated tools.

MSA & Kenexis co-webinar – the new MSA FL5000 Fire Detector and modeling in Effigy™ Fire & Gas Mapping software

This recorded, co-presented webinar begins with Kevin Killeen, Product Line Manager-Flame Detection of MSA, introducing and discussing the new FL5000 fire detector’s features and benefits. From there Edward Marszal, President of Kenexis, explains how to model this new detector’s performance in Effigy™ Fire and Gas Mapping software from Kenexis.

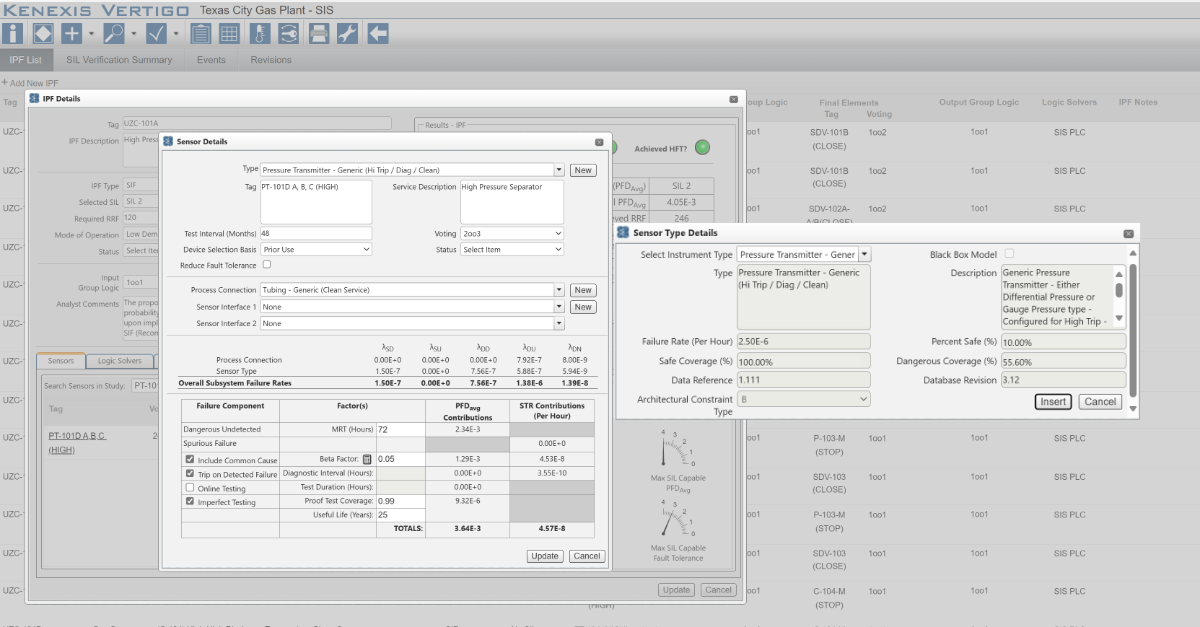

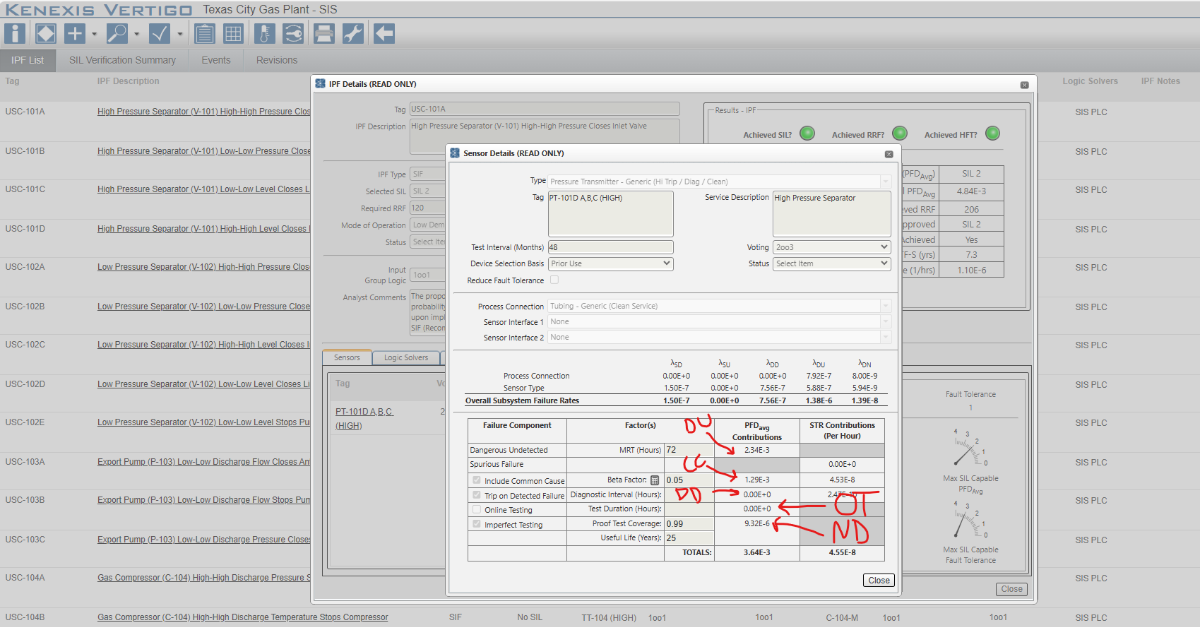

SIL Verification Calculation Terms

This webinar presents all the terms used in SIL verification calculations. The means to calculate and the physical meaning of all the terms are discussed along with their equations – as shown in the IEC EC50 training class on functional safety. The webinar also shows how these terms are treated and displayed in the best-in-class Kenexis Vertigo software for SIS safety lifecycle management.

Safety Requirements Specifications (SRS): Energize-to-Trip Requirements September 2023

One topic in the process industries is known by various names: Fail Safe, ETT, DTT, Deenergize-to-Trip, and Energize-to-Trip. These terms refer to different ways of physically moving a final element in a Safety Instrumented System (SIS) to its safe state. While Deenergized-to-Trip is the most common and preferred approach, it’s essential to consider other factors. Energized-to-Trip systems, where the SIS power drives the final element into the safe condition, can be suitable in certain situations. This webinar discussed the standards requirements for Energized versus Deenergized-to-trip, as well as a workflow to ensure you have adequately considered, designed, and documented the Energized-to-Trip in your SIS design.

Captive Key Interlocks – Description, Use, and LOPA Analysis

Captive key interlocks are one of the most powerful, yet underutilized, safeguards in the process industries. Captive key systems function by preventing a physical action, such as opening a valve, unless an engineered key has been inserted into the valve’s topworks. Once the valve is moved, the key cannot be removed until the valve has been completely cycled. This physical interlocking enforces a specific sequence of operations and prevents valve misalignment, improper opening, and other potentially catastrophic operational errors. These interlocks are simple and effective. Essentially, they can only fail if they are installed incorrectly or physically tampered with, making their PFD dramatically lower than other active safeguarding measures.

This webinar will begin with a description and explanation of operation using a typical application by Ginny Vance of Sofis. Subsequently, Ed Marszal of Kenexis will demonstrate how to account for the use of captive key interlocks in LOPA by presenting a LOPA scenario for the typical oil and gas application of Pig Launcher valve sequencing.

Hydrogen Gas Detection For Electrolyzers

Engineers in the chemical process industries face the task of shifting society away from energy sources that emit carbon dioxide or other greenhouse gases. While numerous methods of storing green energy are being considered, there is significant interest in converting green electricity into chemical energy that is easier to store and transport. The most common approach involves producing hydrogen from water through electrolysis and utilizing the hydrogen directly or converting it into ammonia or other chemicals for improved transportability and energy density.

Hydrogen is emerging as a prominent candidate for driving the transition to green energy. However, like any potential energy source, hydrogen can pose risks if mishandled, as hydrogen is highly flammable, oxygen acts as an oxidizer. Consequently, the release of hydrogen can create hazardous conditions with significant safety implications. To mitigate these risks, a widely used safety measure is the implementation of a gas detection system with automatic shutdown capabilities.

Fault Tree Analysis to Extend LOPA for Shared Components

The Layer of Protection Analysis (LOPA) is widely used in the process industries as a tool to assess hazards and risks. Typically, organizations in the chemical process industry employ a process hazards analysis (PHA) program, which begins with a facilitated workshop study, often using techniques like hazards and operability studies (HAZOP). This study triggers further analysis in certain situations, such as scenarios involving high consequences, complexity, quantitative performance targets for safeguards, very high-cost recommendations, or insufficient risk assessment. In such cases, additional analysis, often more comprehensive than the PHA, is necessary. LOPA is frequently chosen as the technique of choice, as it is more comprehensive than PHA but less resource-intensive than fully quantified risk analysis.

However, there are pitfalls that can make LOPA ineffective and lead to excessively pessimistic results, which may require costly safeguards. If LOPA presents inappropriate results, alternative quantitative tools should be considered to address its limitations. These tools need not be used to their fullest extent, but rather selectively applied to specific applications where LOPA is inadequate. Some of these quantitative tools include dispersion models, explosion models, consequence effects models, event tree analysis, quantitative bowtie analysis, and fault tree analysis.

Adding Gasses and Equipment to Buildings

Altering a building’s original purpose by adding process equipment and dangerous gases can have significant implications for the safety of the building and its occupants. Whether it is apparently minor or major, significant modifications to the building’s structure, electrical and plumbing systems, and ventilation, among other things may be required for safety purposes.

The addition of process equipment and dangerous gases introduces new hazards into the building, including the risk of fire, explosion, and toxic gas leaks. This requires careful planning and implementation to ensure that the building’s safety systems can effectively manage these hazards.

Moreover, regulatory compliance may be necessary to ensure that the building meets all applicable safety standards, such as building codes, environmental regulations, and occupational safety requirements. Failure to comply with these regulations can result in fines, legal liability, and potentially serious safety consequences.

In summary, altering a building’s original purpose by adding process equipment and dangerous gases requires careful planning, implementation, and regulatory compliance to ensure the safety of the building and its occupants.

How to Quickly Determine if Safety Functions are Vulnerable to a Cybersecurity Threat

In this webinar, we will briefly cover the good cybersecurity principles like backing up everything, restricting access, and the other top ten things everyone should already be doing at a minimum. Then we will dive into how to perform a Security PHA Review (SPR) of your HAZOPs. An SPR is designed to help you quickly determine if any of your safety functions are vulnerable to a cybersecurity threat.

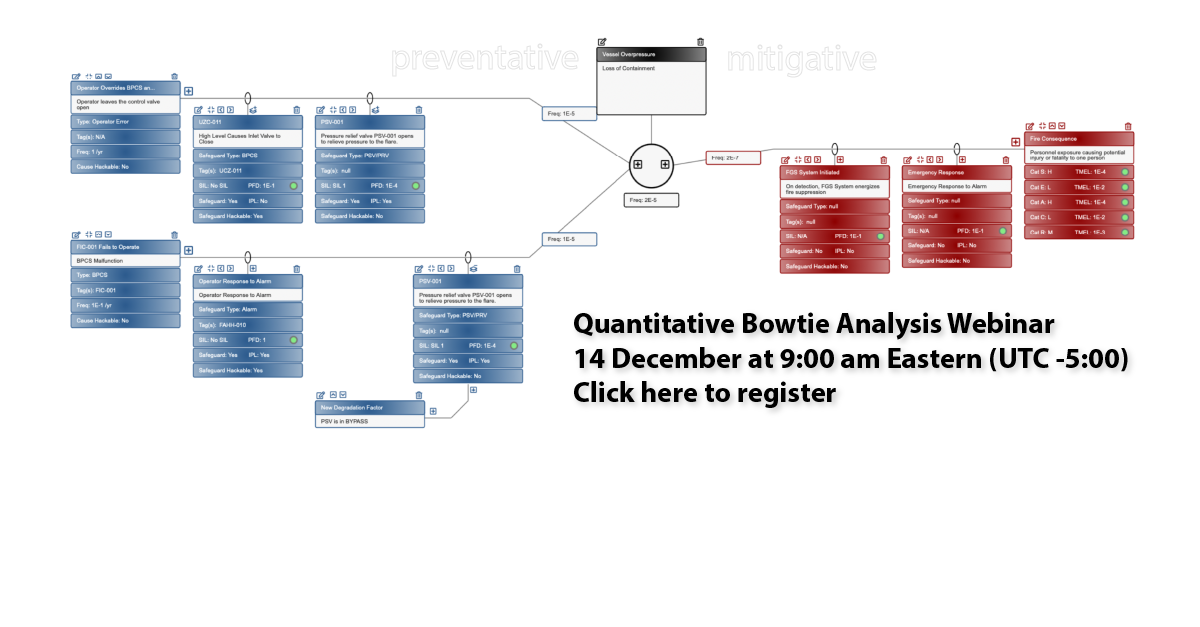

Quantitative Bowtie

Research into Unified Hazard Assessment combining HAZOP, LOPA, and Quantitative Bowtie Analysis has yielded techniques that elegantly address the limitations of LOPA and provided a significantly improved graphical communications method. This recorded webinar provides background on how Unified Hazard Assessment yielded the techniques of Quantitative Bowtie analysis. The webinar will also describe in detail how to implement quantitative bowtie analysis along with the mathematical concepts used for quantification of risk for multiple causes and multiple consequences inside a single scenario. The concepts will be presented using example studies that include mitigative safeguards and multiple cause scenarios.

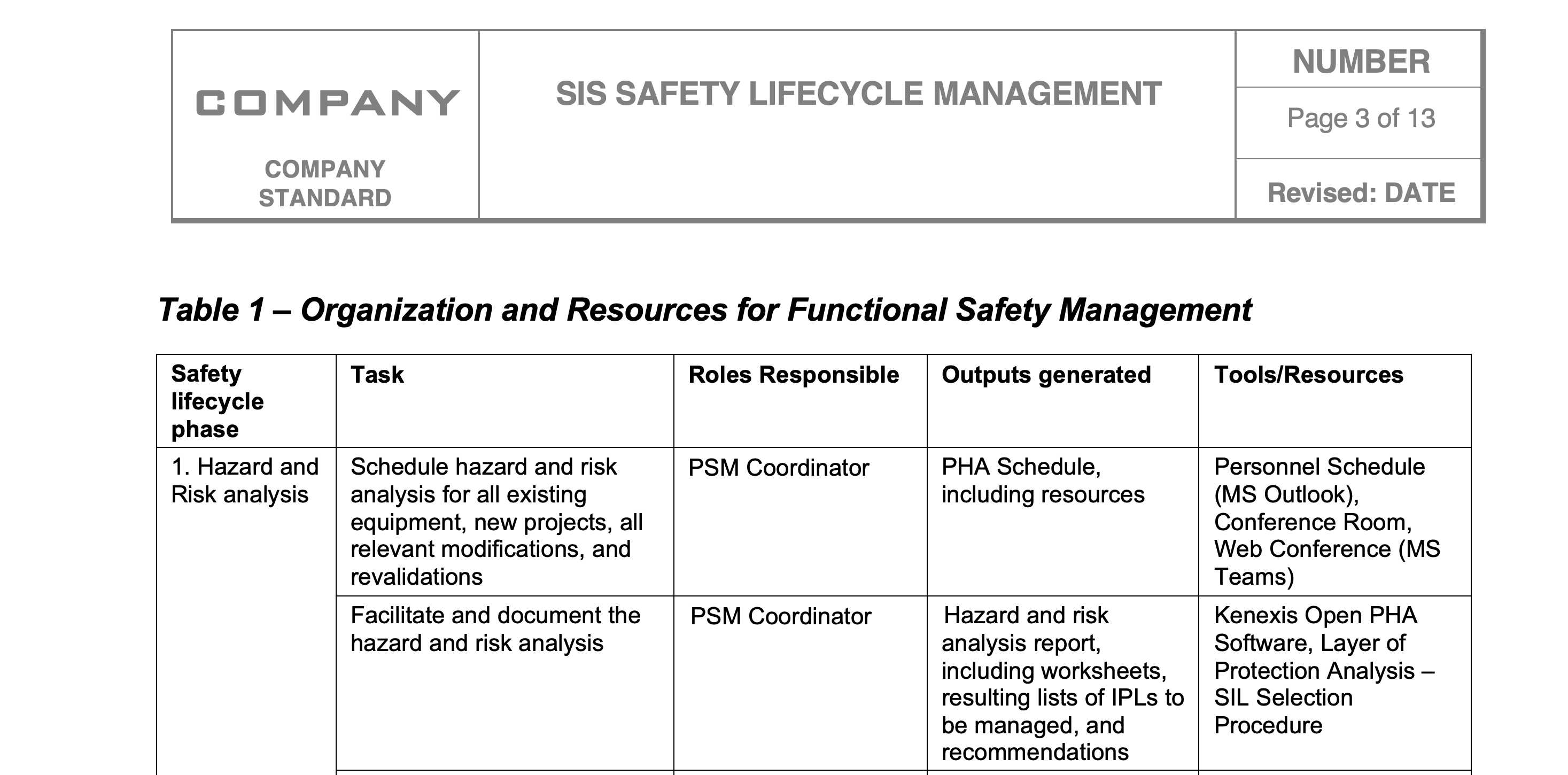

Can I see your Functional Safety Management Program documentation?

Planning Functional Safety (with Template Procedure)

A part of the IEC 61511 standard that does not get the attention that it deserves is clause 5 – Management of Functional Safety.

While most engineers want to focus on detailed design, risk analysis and SIL verification calculations, it is the management aspect that addresses the human failure portion of the risk equation.

In clause 5 we define the need for a plan to be made for functional safety. This plan needs to include the definition of tasks that occur during the SIS safety lifecycle along with assignments of who is responsible for these tasks. This clause also addresses items like competency and the assignment of SIS tasks to external organizations.

In this webinar we will highlight some of the information that is contained in the Kenexis course – SIS Management responsibilities. We will then move on to an explanation of the Kenexis Template SIS Safety Lifecycle Procedure along with recommendations on how to customize it for your organization. If you do not already have a safety lifecycle management procedure, this webinar and the template are a great starting point that will honestly get you most of the way to where you need to be.

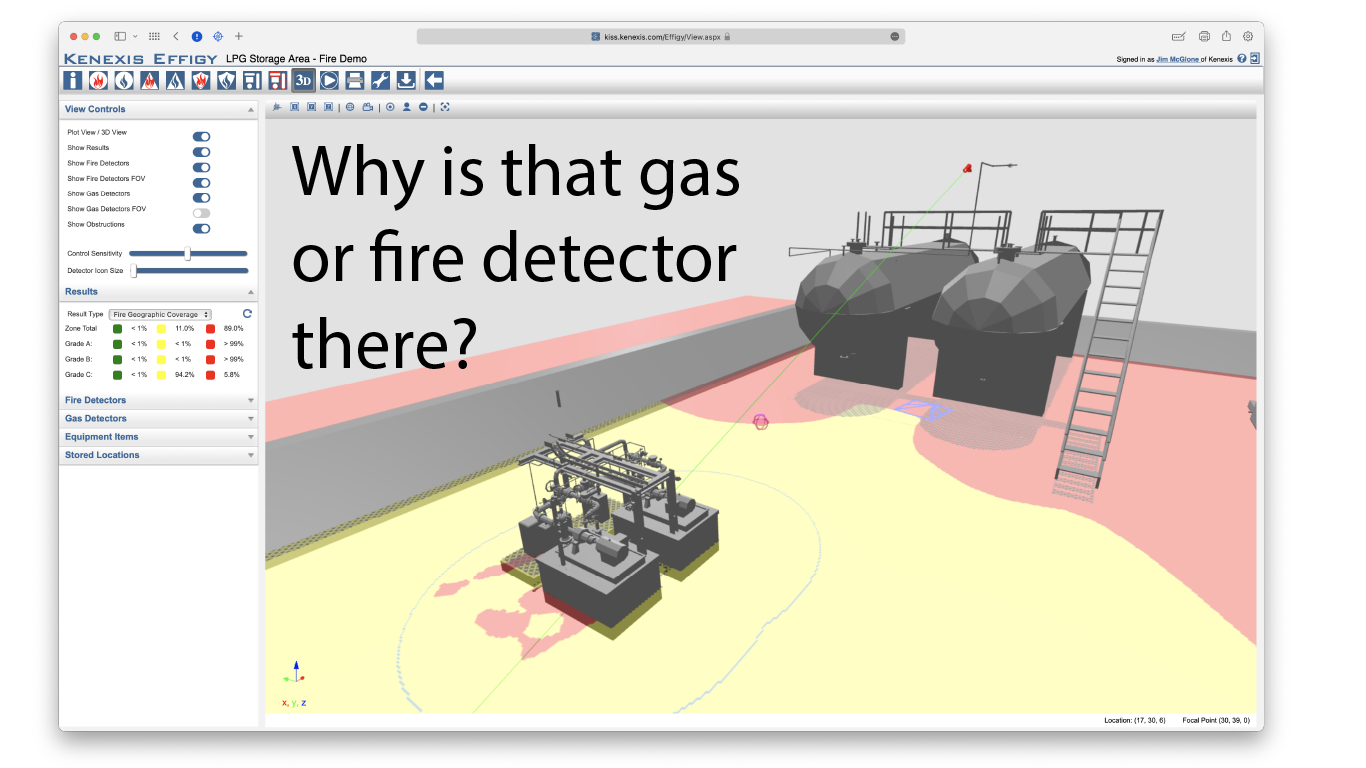

Why is that Detector There

Have you ever wondered why a gas or fire detector is installed at a location. Maybe someone walking through your facility asked you why a detector was installed at a particular location. Scrambling to find an answer at that point is probably useless, you already revealed that you don’t know and maybe no one else onsite knows.

In this webinar we will quickly go through how we engineer where detectors are positioned and some of the science behind the engineering. We will discuss the process and even design a small system live and calculate coverage to see if it meets the requirements.

SIS and BPCS Component Sharing

There is still some confusion about a key attribute of good Safety Instrumented Systems (SIS) design – specifically separation of Basic Process Control Systems (BPCS) and Safety Instrumented Systems (SIS). In this live webinar, we will cover Definitions and Standards Requirements, Assessment of Independence – Shared Valve System, Quantitative Justification of Shared Component, Additional Standards Requirements, Design of SIS Separation Workflow

Risk Assessment and Safeguarding of Lithium Ion Battery Containing Facilities

Join us for a recorded webinar discussing the challenges associated with Risk Assessment and Safeguarding of Lithium Ion Battery Containing Facilities

Problems Blending H2 into Natural Gas (Methane)

Join us for a recorded webinar on discussing some of the Problems Blending H2 into Natural Gas (Methane) including references to the papers and information presented in the video.

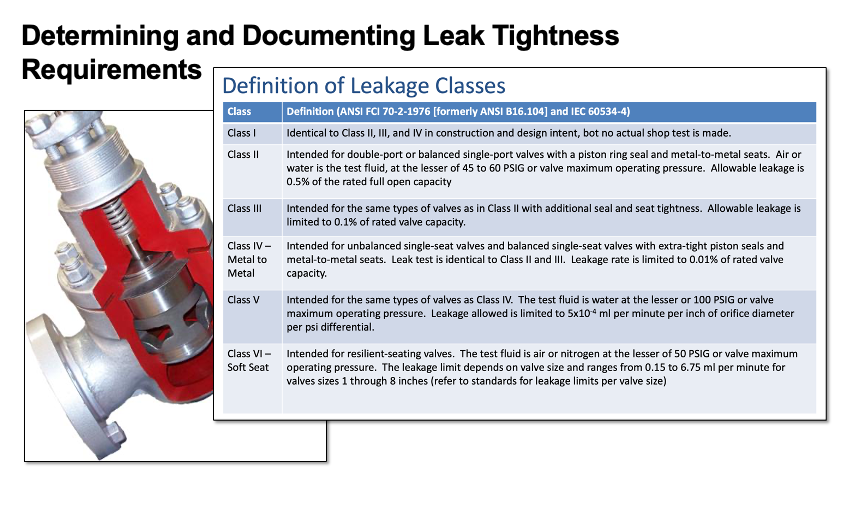

Determining and Documenting Appropriate Leak Tightness Requirements

This webinar goes into detail about the differences between tight shut off and leakage rate methods, the standards, and how to determine the correct leak requirements for your situation.