Is it true that green energy signifies safety?

Is it true that green energy signifies safety?

Green Energy Process Safety Management: Assuming that green energy equates to safety can lead to serious consequences. Storage of substantial energy reserves, whether in the form of hydrocarbons, lithium-ion batteries, compressed hydrogen, or anhydrous ammonia, carries the risk of unintentional energy release, posing threats to both people and the environment. Recent incidents, such as the hospitalization of first responders tackling fires and explosions at facilities storing solar power in lithium-ion batteries, underscore that no energy storage method is exempt from catastrophic accidents. As the adoption of new green technologies grows, it’s imperative for manufacturers and users alike to proactively plan and implement measures to avert major accidents that could hinder the widespread adoption of these technologies.

Hydrogen

Hydrogen

Hydrogen holds immense promise as an energy source, yet it also presents inherent dangers, distinguishing it substantially from methane-based products like natural gas and propane. One notable risk is the phenomenon known as hydrogen permeation, which warrants exploration below.

Hydrogen permeation manifests in industrial pressure transmitters, particularly those operating in high-pressure hydrogen environments. This occurrence occurs when hydrogen ions (H+) infiltrate the lattice structure of the diaphragm, leading to significant inaccuracies in pressure measurement.

In its diatomic form, hydrogen cannot breach the lattice structure of the diaphragm. However, as H+ ions, its reduced size enables penetration, reforming into H2 molecules on the diaphragm’s rear surface. Trapped hydrogen induces zero or span shifts in the pressure transmitter, progressively compromising its accuracy over time.

Typically observed in units with H2 pressures exceeding 1000 psig, measures to mitigate this phenomenon often involve employing specialized diaphragms, such as gold-plated ones, to impede permeation. Nonetheless, even these diaphragms aren’t entirely immune, and in high-pressure settings (above 1,500 psig), they may experience considerable drift within a few years. This drift could yield errors ranging from 200-300 psig lower than the actual pressure.

The impact varies based on whether the transmitter’s sides are sealed or vented. In the case of a vented transmitter, hydrogen is released into the atmosphere through the vented side of the diaphragm.

In summary, hydrogen permeation poses a significant risk to industrial pressure transmitters, necessitating the use of specialized diaphragms in high-pressure hydrogen environments. Regular transmitter replacement is advised to mitigate drift and maintain precise pressure measurement.

Kenexis

Kenexis

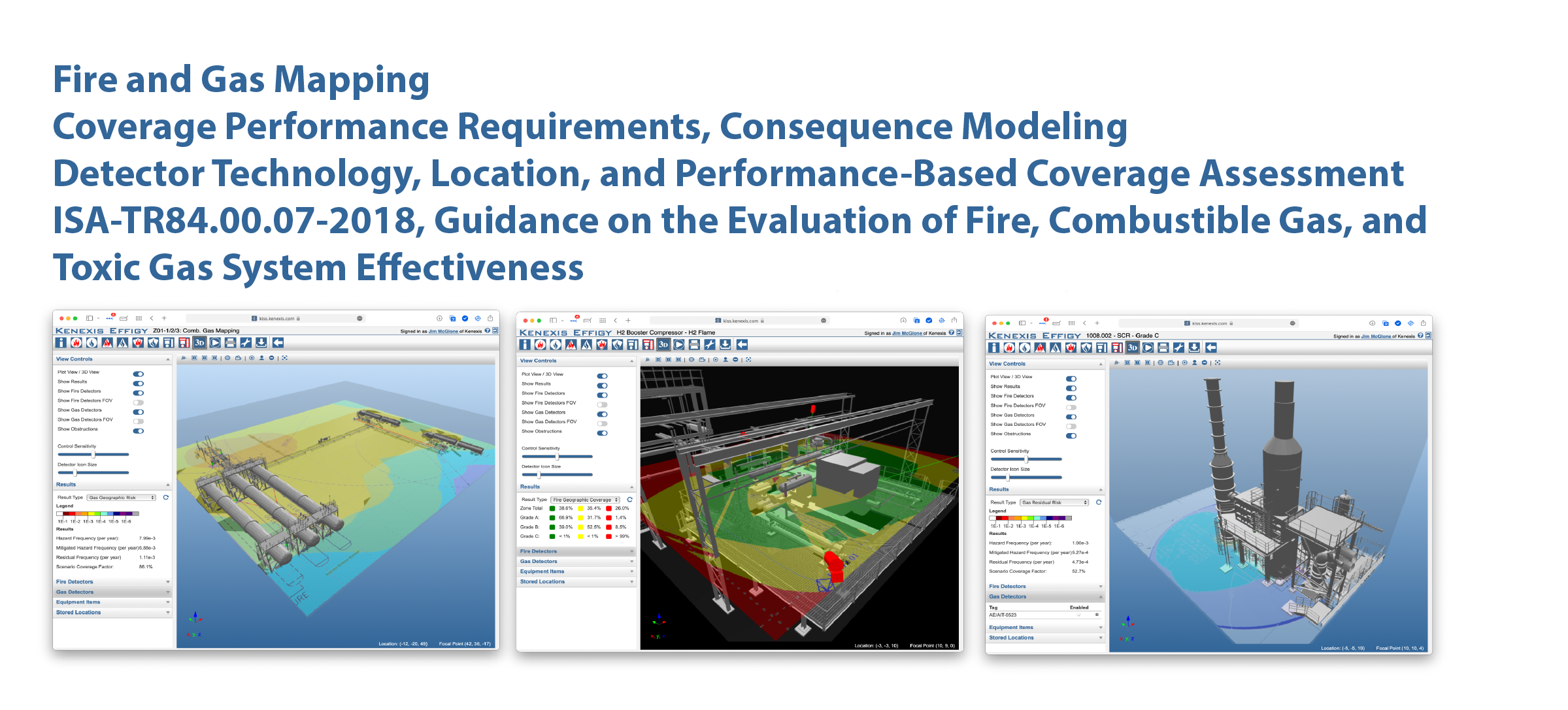

Here’s where Kenexis can help. With unmatched expertise, we specialize in analyzing and safeguarding against the hazards of green technology. We utilize proven engineering methodologies, including Hazards and Operability Studies (HAZOP), gas dispersion and explosion modeling, design of SIS (safety instrumented systems) for emergency shutdown, and placement and design of gas detection and fire detection systems. Our approach also includes facility siting to ensure proper separation of equipment and occupied buildings.

Some of the processes for which we have conducted successful analyses and developed safety solutions to ensure the management of Green Energy process safety:

Test Cells

Testing facilities for charging and discharging Li-Ion batteries within confined spaces present a distinct set of risks, unlike those found in traditional petroleum-based facilities. Kenexis has demonstrated that these new hazards can be effectively managed using established techniques from the process industries. We identify additional hazards not addressed by building codes, assess their consequences, and establish performance targets for fire and gas systems accordingly. Through modeling gas releases and fire likelihood, we pinpoint optimal locations for fire and gas detection equipment, ensuring early detection of gas leaks or fires. Our rigorous verification process ensures that the proposed detector layout meets coverage performance objectives.

Lithium-Ion Battery Development

Manufacturers of lithium-ion batteries must not only address hazards in their production processes but also consider liability for accidents experienced by their customers during product usage. Evaluation of lithium-ion battery production facilities and processes should involve Process Hazard Analysis (PHA). PHA often leads to recommendations for various safeguards, including Safety Instrumented Systems (SIS) and fire and gas detection systems. Storage of chemicals used in battery production should also consider the proximity of storage vessels and processes to occupied rooms and buildings, as part of facility siting considerations.

After battery manufacturing, testing, and informing consumers about potential hazards and emergency responses are crucial for maintaining positive relations. Lithium-ion batteries typically contain highly reactive chemicals, whose decomposition can lead to the release of toxic substances into the atmosphere. Testing should be conducted to help users understand potential issues and appropriate responses. This includes calorimetry testing to determine parameters such as self-accelerating decomposition temperature (SADT), Temperature of No-Return (NRT), energy released during decomposition, reaction rate constants, and composition of materials released. This information enables large-scale users of batteries to implement suitable safeguards using SIS and fire and gas detection systems in their facilities.

Lithium-Ion Battery Applications

Lithium-ion batteries are composed of materials that present risks of fire, explosion, and exposure to toxic substances. These batteries typically contain electrolyte systems, often with lithium hexafluorophosphate (LiPF6) as the electrolyte dissolved in a solvent like ethylene carbonate. Experience and studies have shown that these systems can undergo self-accelerating decomposition and thermal runaway, leading to the release of flammable gases such as CO, CH4, and C2H4, as well as toxic chemicals like HF and POF. Large-scale incidents involving multiple cells have resulted in significant fires and facility explosions due to the accumulation of decomposition byproducts. Analysis indicates that even a small release of hydrogen fluoride (HF), an extremely toxic substance with an immediately dangerous to life and health (IDLH) value of 30 parts per million (PPM), could cause harm to humans in confined spaces, such as those found in a single hybrid automobile battery system.

Kenexis offers expertise in safeguarding facilities that employ Li-Ion battery systems, such as automotive test and production facilities. This safeguarding process begins with a thorough Process Hazards Analysis (PHA), often conducted through methods like failure modes and effects analysis (FMEA) or hazard and operability studies (HAZOP). These analyses typically lead to recommendations for implementing safeguards. Common safeguards for Li-Ion battery systems include Safety Instrumented Systems (SIS) to detect thermal runaway and halt the process, along with potential measures for external cooling. In the event of thermal runaway, it is crucial to protect personnel and facilities from its effects. This involves utilizing gas dispersion analysis to strategically place gas detectors capable of indicating the extent and location of hazardous conditions, as well as employing fire detection mapping to position optical fire detectors for early fire detection and mitigation. Data from these detectors can be integrated into SIS to trigger actions such as fire suppression and ventilation adjustments. Additionally, the proximity of hazard-containing areas to regularly occupied spaces should be considered in facility siting analyses.

Hydrogen Fuel Cell Applications

The utilization of hydrogen fuel cells for electricity generation brings about inherent hazards associated with hydrogen. Hydrogen, being a flammable gas, has the potential to cause explosions if ignited, especially when confined. Notably, hydrogen fires pose significant dangers as they are invisible to the human eye. Facilities incorporating hydrogen fuel cells should conduct a thorough Process Hazard Analysis (PHA) to pinpoint potential risks.

Gas dispersion modeling is essential to identify areas where hydrogen leaks could accumulate and potentially ignite, leading to explosions. In case such locations are identified, the implementation of gas detection systems becomes imperative. Furthermore, fire detection mapping should be utilized to determine the necessary quantity and placement of fire detectors for early detection and response to incidents involving these “invisible” fires.

Lastly, facility siting considerations are crucial to ensure that occupied rooms and buildings are adequately distanced from areas where explosions could potentially occur. This ensures the safety of occupants and minimizes the risk of harm in the event of an explosion.

Hydrogen Production and Storage

The generation of electricity from hydrogen fuel cells carries inherent hazards associated with hydrogen. Hydrogen, being a flammable gas, can readily explode if ignited when confined. Hydrogen fires pose a particular danger as they are not visible to the human eye. Facilities utilizing hydrogen fuel cells should conduct Process Hazard Analysis (PHA) to pinpoint potential hazards. Gas dispersion modeling should be utilized to identify areas where hydrogen leaks could accumulate and potentially ignite, leading to explosions. If such locations are identified, gas detection systems should be implemented. Additionally, fire detection mapping should be employed to determine the necessary number and placement of fire detectors to detect and respond to any incidents of these “invisible” fires. Finally, facility siting considerations should be taken into account to ensure that occupied rooms and buildings are adequately distanced from areas where explosions could potentially occur.

Ammonia Production, Storage, and Transportation

Ammonia has traditionally been perceived as neither environmentally friendly nor innovative, often associated with its conventional roles as a fertilizer or household cleaner. However, this perception is anticipated to change soon. While the potential of hydrogen as a green energy source is well recognized, its transportation and storage pose significant challenges and expenses. Ammonia is emerging as a promising intermediary for hydrogen utilization, particularly in transportation and storage applications. Mature process technology enables the efficient conversion of hydrogen into ammonia, which can then be stored and transported as liquid anhydrous ammonia. This form of ammonia boasts over ten times the energy density of lithium-ion batteries and significantly surpasses compressed hydrogen in terms of energy storage capacity. Upon reaching its destination, the ammonia is cracked back into nitrogen, returning it to the atmosphere, and hydrogen, which can be utilized in fuel cells.

Although ammonia production processes are well-established and deemed safe, it is crucial to manage associated hazards such as flammability and toxicity. This risk management process typically commences with Process Hazard Analysis (PHA). Safety Instrumented Systems (SIS) are commonly deployed at various points throughout the process to safeguard equipment and prevent containment breaches. Given the presence of flammable and toxic materials, gas dispersion modeling is essential for determining optimal locations for gas detection systems. Additionally, safeguarding equipment against fire hazards involves comprehensive fire detection coverage mapping. As with any large-scale industrial facility handling chemicals, meticulous facility siting is imperative to ensure adequate separation between occupied areas and zones where fires, explosions, and toxic releases could potentially occur.

Ethanol Production

Ethanol, an early entrant in the realm of green energy, is primarily derived from the fermentation and distillation of corn for use as a motor fuel supplement alongside hydrocarbon-based fuels. While ethanol currently serves as a widely utilized energy source, its prominence is anticipated to diminish as automobiles increasingly transition towards electrification via batteries or hydrogen fuel cells, leading to a decline in gasoline usage. However, ethanol remains a staple in today’s energy landscape and is projected to maintain its relevance in the immediate and medium-term future.

As a flammable liquid, ethanol poses hazards similar to other combustible liquids. Therefore, conducting a thorough Process Hazard Analysis (PHA) is essential to comprehensively assess the risks associated with the ethanol production process and its equipment. Implementation of Safety Instrumented Systems (SIS) is advisable, particularly if natural gas-fired heaters are utilized for tasks such as reboiling distillation columns or steam production. While the utilization of fire and gas detection systems may be warranted, their relevance is relatively lower compared to facilities with higher risk profiles.

Although flammable, ethanol is a liquid under standard ambient conditions and does not exhibit significant toxic properties through inhalation. Nonetheless, facility siting considerations should be prioritized for ethanol production facilities due to the inherent flammability concerns associated with the substance.

Biodiesel Production

Biodiesel and biokerosene represent another category of environmentally friendly liquid fuels. These alternatives can serve as substitutes for diesel and kerosene, both of which are typically derived from petroleum. Even as the automotive industry transitions towards electric vehicles, biodiesel and biokerosene are expected to maintain relevance in the green energy landscape, particularly for heavy trucking and air transportation, where highly energy-dense fuels are essential. Unlike traditional fuels, biodiesel and biokerosene are produced from fats (oils) sourced from living organisms, such as plants or algae. These fats undergo a process called transesterification to yield methyl esters, the final product, and glycerin.

However, the production process is notably intricate due to the presence of contaminants in plant oils that can be incompatible with engine systems or lead to environmentally undesirable combustion byproducts. Consequently, additional treatment steps are necessary, including hydrotreating for desulfurization and hydrogenation to saturate olefinic bonds in the ester’s hydrocarbon chain.

Biodiesel refineries incorporating hydrogenation and hydrodesulfurization processes can pose significant hazards. As expected, the foundation of process safety management for biodiesel production is the Process Hazard Analysis (PHA), which assesses the need for Safety Instrumented Systems (SIS) and fire and gas detection systems. Hydrodesulfurization, occurring under high temperature and pressure, presents a risk of thermal runaway, necessitating extensive SIS equipment. Given the use of hydrogen at high pressure, gas dispersion modeling for gas detector placement and fire detection, especially near compressors, is imperative. Moreover, the hydrogen required for desulfurization and hydrogenation entails similar process safety management considerations as any other hydrogen production facility, whether producing blue hydrogen (more common) or green hydrogen (less common). As always, facility siting considerations must be taken into account during the layout of process equipment to ensure safe operations.

Get in touch with us at [email protected] to discuss your challenges and let us assist you in ensuring the safety and sustainability of your processes.

Is it true that green energy signifies safety?

Is it true that green energy signifies safety? Hydrogen

Hydrogen Kenexis

Kenexis